If your belts touch food, they’re part of your food-contact surface program—and that means hygiene, compliance, and documentation are non‑negotiable. This food-grade conveyor belt selection checklist helps procurement, maintenance, and QA teams specify, evaluate, and verify belts that truly fit your process.

Food-grade conveyor belt selection checklist (compliance-first)

Use this as a runnable list during specification, supplier evaluation, FAT/SAT, and audits.

-

Compliance & Declaration of Compliance (DoC)

- Request an EU Plastics Regulation DoC whenever plastics are present. Confirm it follows Article 15/Annex IV (identity, material description, intended use, restrictions/conditions including time/temperature and food types, and references to supporting documentation available to authorities). See the European Commission’s overview of food contact materials legislation.

-

FDA applicability (U.S. plants)

- For rubber or polymeric coatings used repeatedly, ask for written statements of compliance to FDA Title 21—e.g., 21 CFR 177.2600 where applicable—and supporting extraction/migration data under the specified test conditions. Reference the eCFR Part 177 index for indirect food additives to align your request with the correct subsection.

-

FSMA preventive controls alignment

- Ensure sanitation preventive controls for belts are written, monitored, and verified (including environmental monitoring where RTE hazards exist), with records and corrective actions per 21 CFR Part 117. FDA resources and warning letters illustrate expectations; consult the FDA’s preventive controls guidance chapters linked from their site.

-

Migration/extractives testing evidence

- Obtain EU overall migration (OML ≤10 mg/dm² or 60 mg/kg) and specific migration (SML) reports with test conditions (simulant, time, temperature, surface area) per EN 1186/EN 13130, where applicable. For the U.S., request extractives/migration data per the relevant 21 CFR provision (e.g., 177.2600 for rubber).

-

GMP and traceability

- Verify manufacturing under (EC) 2023/2006 Good Manufacturing Practice and EU 1935/2004 traceability. The Commission’s FCM portal outlines these obligations.

-

Keep EU updates in view

- Plastics rules evolve. Confirm your supplier’s DoC reflects amendments to EU 10/2011—such as Commission Regulation (EU) 2025/351—before approval, especially for repeated‑use plastics and any recycled content declarations.

-

Material selection documented

- Record product characteristics (temperature, moisture, fat/oil, acidity, stickiness, abrasiveness) and select a material family (TPU/PU, PVC, silicone, modular PP/PE/POM, stainless). Attach the belt’s datasheet with operating temperature and chemical compatibility limits.

-

Hygiene & cleanability checks

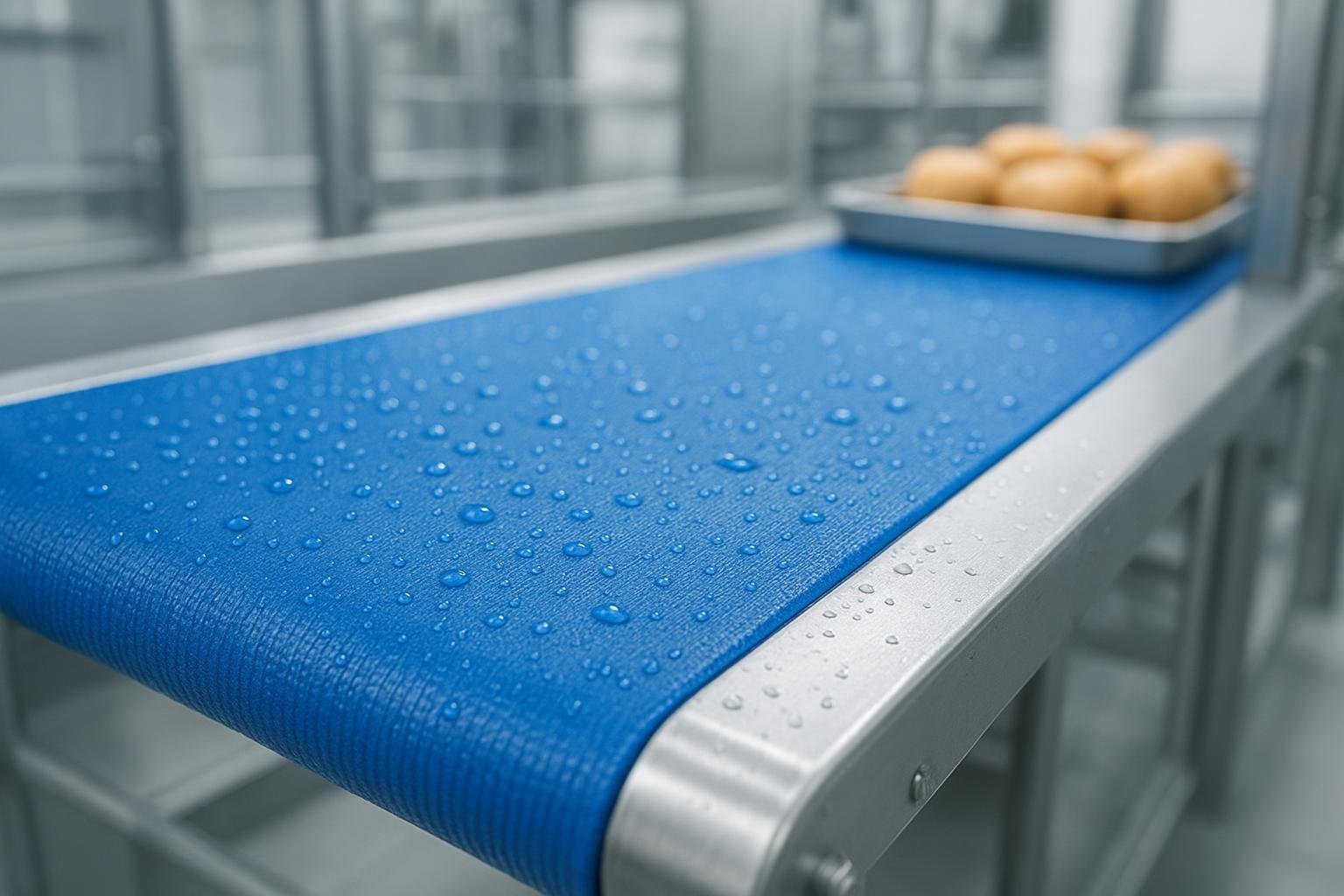

- Inspect for smooth, non‑porous belt surfaces, hygienic joints/splices, and—on coated fabric belts—edge sealing to prevent wicking and fray. EHEDG guidance on hygienic conveyor design highlights minimizing crevices and facilitating effective wet cleaning; see the EHEDG overview of belt conveyor hygiene best practices.

-

Drive type and geometry

- In wet/oily zones, prefer positive‑drive solutions to reduce slippage and tension; match sprocket pitch/spec for modular belts. For small product transfers, confirm nosebar or transfer roller geometry fits the product size to avoid damage and residue traps.

-

Cleaning chemicals and washdown limits

- Confirm compatibility with your disinfectants (peracetic acid, chlorine, caustic) and maximum washdown temperature/concentration from the supplier’s datasheet or compatibility charts. Many vendors provide chemical resistance tools; validate against your site’s regimens.

- Detectability & color (CCPs)

- If your HACCP plan requires it, specify metal- or X‑ray‑detectable belt options and document the minimum detectable sizes validated on your installed systems. X‑ray inspection capability often ranges around 0.8–1.8 mm stainless spheres depending on product density and setup, per Thermo Fisher’s industrial food X‑ray guidance. Choose belt colors (commonly blue) that enhance residue visibility and ensure permitted colorants.

- Installation & maintenance SOPs

- Define splice type and verification, tensioning/tracking procedures, changeover steps, inspection intervals (edge integrity, cracks, wicking, fray), and spare parts lists. Keep records aligned with FSMA verification.

- Validation & audits

- Link belts to HACCP/PRP controls, maintain sanitation validation records (e.g., ATP or bioburden swabbing plans and results), and re‑validate after belt replacements, repairs, chemical changes, or process modifications.

Red flags to watch:

- Vague “food grade” claims without specific regulatory citations or test reports.

- DoC missing intended use conditions (time/temp/food type) or SML references.

- No batch/lot traceability or change notification process.

Choose the right belt material for your application

Your choice should reflect product characteristics, process temperatures, cleaning regimens, and hygiene goals. Think of it this way: match the belt’s surface behavior and durability to your soil load and sanitation method, not just the production rate.

| Material | Typical operating range | Release/cleanability | Oil/fat resistance | Typical uses |

|---|---|---|---|---|

| PU/TPU | ~up to 100°C continuous; peaks to ~130°C for specialty TPU (model‑specific) | Good to excellent; monolithic TPU variants minimize crevices | Good; engineered TPU supports many sanitizers | General plant use; wet/oily lines; incline conveyors |

| PVC | ~−15°C to +80–100°C (series‑dependent) | Good on non‑porous coated surfaces | Moderate; select oil‑resistant grades | Dry or moderate washdown lines; packaging |

| Silicone (coated) | ~up to 180–190°C continuous; excellent non‑stick | Excellent release; smooth, cleanable | Good chemical/hydrolysis resistance | Sticky/high‑sugar products; baking contact |

| Modular plastics (PP/PE/POM) | ~−70°C to +240°C across resins; POM ~−40°C to +93–100°C dry | High; open hinge design aids cleaning when specified well | Material‑dependent; validate against disinfectants | Freezer lines (PE), general conveying (POM), higher temp (PP) |

| Stainless steel (mesh/flat wire) | ~to 370–427°C typical; higher with special alloys | Excellent washability; open mesh drainability | N/A (metallic) | Baking, frying, high‑temp processes |

Notes:

- Ranges are typical—always confirm per belt SKU in the datasheet.

- For sticky products, silicone or specific TPU release surfaces reduce residue and cleaning time.

- For heavy washdown or oily environments, monolithic TPU positive‑drive or modular positive‑drive belts often improve hygiene and control.

Hygiene and cleanability details you must verify

Smooth, closed surfaces and crevice‑free joints are your friends. On coated fabric belts (TPU/PVC), confirm edge sealing to prevent liquid ingress, wicking, and fray. Hygienic splice methods (e.g., heat‑sealed overlaps or butt joints for silicone/PTFE; monolithic belt splices designed for sanitation) reduce harborage. EHEDG’s guidance on conveyor hygiene emphasizes accessible cleaning, protected drives, and drainable frames; it’s a practical benchmark for the interfaces around your belt.

Cleaning chemicals matter as much as material choice. Incompatible disinfectants can cause cracking, swelling, or embrittlement, raising foreign material and hygiene risks. Validate chemical compatibility and maximum washdown temperature against the supplier’s charts or tools, and write those limits into your SOPs.

Drive type and geometry choices in wet, oily, or delicate product handling

Positive‑drive belts engage mechanically with sprockets, which helps control slippage at low tension and can simplify sanitation around the drive. They’re often preferred in wet or oily zones. Friction‑drive belts suit dry or light duty where tensioned contact is stable and hygiene demands are lower. For delicate or small products, ensure transfer geometry (nosebars, small‑diameter rollers) and belt pitch allow clean transfers without product damage or residue traps.

Detectability and color for CCPs and visual inspection

If your HACCP plan calls for a detectable belt, don’t rely on marketing claims—validate detectability on your installed equipment with your actual products. Record minimum detectable sizes and test pieces. X‑ray performance depends on product density and setup; typical ranges often show stainless spheres around 0.8–1.8 mm, but your line may differ. Metal detector sensitivity drops in wet/salty foods; consider multiscan or multifrequency systems if needed. Choose colors that heighten residue visibility; many plants pick blue for contrast. Ensure any colorants in the belt comply with the relevant food‑contact rules (EU SMLs; FDA‑permitted colorants in listed polymers).

Installation, maintenance, and audit readiness

Define who signs off on belt installation (FAT/SAT), the splice/joint verification steps, and acceptance criteria for tracking and tensioning. Set inspection intervals for edge integrity, cracks, and wear, and track corrective actions. Link belt maintenance records to your FSMA verification files. When belts, chemicals, or process conditions change, trigger re‑validation and update your HACCP documentation.

FAQs: compliance and practical selection

-

What’s the difference between FDA and EU compliance for belts?

- FDA’s Title 21 provisions (e.g., 21 CFR 177.2600 for rubber articles for repeated use) govern permitted substances and extraction limits. The EU’s framework (EC 1935/2004) and Plastics Regulation (EU 10/2011) set overall and specific migration limits, with DoC and GMP obligations. Start with the European Commission’s legislation overview, then align your supplier documents to your market.

-

Do I really need positive‑drive in wet/oily applications?

- Often, yes—it reduces slippage and simplifies tension management, which supports hygiene aims. Validate with your process soils and sanitation routine; monolithic TPU and certain modular belts are widely used in these zones.

-

How do I handle detectability requirements?

- If your CCP requires detectable belts, specify the detection method (metal or X‑ray), obtain documented test methods and thresholds, and validate with your products. Typical capability ranges should be confirmed on site with your equipment.

-

What washdown limits should I set?

- Include maximum temperature and chemical concentrations from the belt datasheet or supplier compatibility charts in your SOPs. Re‑verify after sanitizer changes—material behavior can shift with chemistry.

Apply this food-grade conveyor belt selection checklist to your next specification or audit, and adapt the items to your HACCP plan, product mix, and sanitation program. The right belt, validated the right way, helps keep food safety and uptime on track.