If product damage is creeping into your scrap reports—or worse, your customers are spotting scuffs, chips, or cracked seals—you don’t just lose units. You lose confidence, uptime, and margin. This guide distills proven practices for selecting and designing a conveyor for fragile products across food, electronics, glass, and packaging lines, anchored by standards and supplier guidance.

Quick decision checklist before you spec anything

- Define product parameters: mass/weight per item, dimensions, center of gravity, and packaging stiffness.

- Rate fragility: susceptibility to impact, vibration, scratching, tipping, or static discharge.

- Map transfers: where do handoffs occur (infeed/outfeed, curve-to-straight, belt-to-belt), and what gaps must be bridged?

- Set hygiene/cleanability requirements: food-contact? washdown routine? CIP? targeted surface finishes.

- Establish ESD control needs: electronics or glass lines in an EPA? grounding/ionization required?

- Decide accumulation logic: zero-contact (zero-pressure accumulation) or short dwell with minimal back pressure.

Conveyor classes and where they fit for a conveyor for fragile products

Choosing the right class is half the battle. Think of classes like “behavior templates”—each brings characteristic contact geometry, traction, and cleanability. Where numeric ranges are mentioned, treat them as starting points and validate on your product.

Flat belts and soft-touch coated fabrics

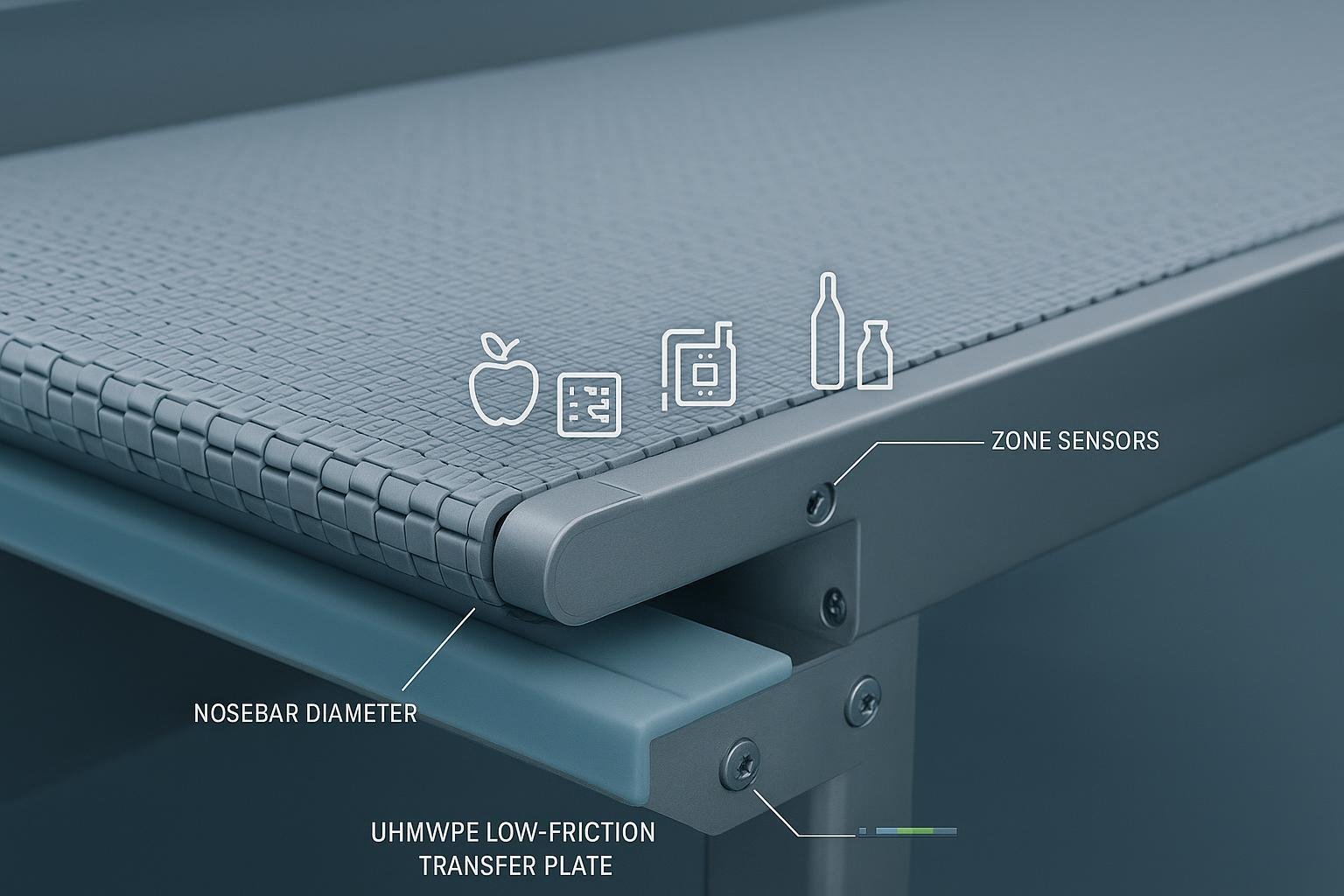

Flat belts provide continuous support with minimal vibration. Coated fabrics (e.g., PU with soft-touch top) reduce micro-scratching for packaged goods and bakery items. Knife-edge (nosebar) transfers with small diameters—down to about 12.7 mm, 24–32 mm, or 48 mm depending on belt—help small items clear the gap without dropping. Dorner’s manuals detail these nosebar options and belt compatibilities; some belts cannot be V‑guided around very small rollers, so confirm tracking method before finalizing. See the vendor’s guidance in the Dorner AquPruf and 3200 Series manuals: nosebar diameters and belt compatibility y 3200 Series manual.

Modular plastic and open‑grid belts (sanitation‑friendly)

For food lines, open‑grid modular belts enable washdown and drainage while maintaining gentle support. Pair with stainless frames and cleanable guide rails. Tight‑transfer modules or dynamic nose rollers reduce dead plates that can scuff or catch edges. Intralox has documented benefits of dead‑plate‑free tight transfers for beverage and container lines—reducing complaints tied to scraping and impact—see their overview on dead‑plate‑free tight transfers.

Vacuum or air‑assist conveyors

When you can’t allow tipping or sliding (thin cartons, light trays), vacuum hold‑down belts stabilize parts through transfers and elevation changes. Use conservative speeds; validate that suction does not deform packaging or mark surfaces.

Tabletop chain and roller‑top accumulation

Tabletop chain supports rigid containers and cartons; roller‑top modular belts help decouple drive traction from product contact, lowering back pressure during accumulation. Synchronize speeds at handoffs to avoid micro‑impacts and scuffing; eliminate dead plates where feasible.

Spiral/vertical and incline conveyors

For soft packages or fragile bakery items, pick belts with compliant surfaces and add side guards/rails with UHMW contact strips. For inclines, chevron or high‑friction tops reduce slippage; consider gentle acceleration profiles and shorter drops at transitions.

Accumulation: why zero pressure matters

Zero‑pressure accumulation (ZPA) divides the conveyor into zones so products never collide under back pressure. This is one of the simplest, most effective ways to protect fragile goods during stoppages. Hytrol’s ZPA systems and Interroll’s ZoneControl/MultiControl document one‑item‑per‑zone logic, sensor signaling, and soft starts. See Hytrol’s ZPA overview and Interroll’s ZoneControl manual.

Transfers: knife‑edge, UHMWPE plates, and dead‑plate‑free designs

- Knife‑edge/nosebar transfers minimize the gap, reducing drop energy for small or delicate items. Validate belt compatibility with small rollers.

- UHMWPE low‑friction transfer plates can bridge unavoidable gaps and reduce scratching. Dorner documents UHMW accessories and transfer methods; see the discussion of transfer method pros and cons.

- Dead‑plate‑free tight transfers (e.g., dynamic nose rollers) reduce scraping on glass bottles and similarly delicate containers—see the Intralox guidance above.

Component selection for gentle handling

Use components that lower contact forces, prevent abrasion, and keep tracking stable.

Issue–solution mapping:

| Issue | Preferred component/setting | Notes |

|---|---|---|

| Back pressure damage in queues | Zero‑pressure accumulation zones with photoeyes | Document zone length vs. product length; verify stop/start profiles |

| Scratching at transfers | Knife‑edge/nosebar, UHMWPE transfer plates | Confirm belt compatibility and plate thickness; minimize gaps |

| Tipping at handoffs | Synchronized drives and guide‑rail geometry | Align heights; add side rails with UHMW strips |

| Vibration scuffing | UHMWPE or coated belts; balanced idler spacing | Use low‑runout pulleys; check belt tension |

| Tracking drift | Crowned pulleys or V‑guides (where compatible) | Some belts can’t be V‑guided around small rollers |

| Static discharge risk | Dissipative belts/rollers; grounding; ionizers | Align with ANSI/ESD S20.20/IEC ranges |

Idlers and pulleys

- Idlers: UHMWPE or coated rollers reduce friction and noise; stainless or ceramic lagging improves traction in wet areas.

- Pulleys: Consider crowned pulleys for tracking on belts compatible with crowning; verify surface finish in food areas.

- Guides and rails: Use low‑friction liners (UHMWPE/PTFE) and set clearances to prevent edge scraping.

Controls, dynamics, and ESD control

Gentle handling isn’t only mechanical—it’s dynamic.

- Zone control: Photoelectric sensors per zone with stop/start logic yield reliable ZPA. Interroll’s manuals outline peer‑to‑peer signaling and diagnostics in modular setups—see the ZoneControl manual.

- Accel/decel and jerk limits: Modern VFDs and motion controllers (e.g., Rockwell PowerFlex “TotalFORCE”) support configurable ramps and jerk‑limited profiles that reduce sudden changes in force. Confirm capability in your drive family; see Rockwell’s overview of TotalFORCE control features.

- Synchronization: Match speeds at infeed/outfeed to avoid micro‑collisions. Use encoders and simple PLC logic to trim setpoints.

- ESD control: In electronics and certain glass operations, choose conductive/dissipative materials consistent with ANSI/ESD S20.20 and IEC 61340‑5‑1 ranges. Ground frames and bonding points; verify footwear/flooring systems and use ionizers for unavoidable insulators. The ESD Association’s materials summarize resistance categories and program elements—see their overview on ESD control programs and comparisons of ANSI/ESD S20.20 vs. IEC 61340‑5‑1.

Sanitary design and materials for food applications

Food‑contact conveyors must be hygienic by design. The FDA’s CGMP rules (21 CFR Part 117) require equipment that’s cleanable and prevents contamination—including managing drip and condensate risk. See FDA’s CGMP references and enforcement letters for practical expectations, such as in their CGMP overview materials.

Apply 3‑A and EHEDG principles: smooth finishes (often around 32 microinch/0.8 μm Ra or better), proper drainage, radiused corners, and accessibility for inspection and cleaning. 3‑A SSI’s primers and EHEDG’s yearbook explain these fundamentals—see the 3‑A primer on sanitary standards y el EHEDG Yearbook 2023 guidance.

What does this mean in practice?

- Use stainless frames and fasteners suitable for washdown; seal or elevate bearings away from splash zones.

- Prefer open‑grid modular belts where frequent washdown is required; ensure tool‑less removal for cleaning.

- Specify accessible guard and rail designs; avoid harborage points.

Validation: FAT/SAT template for fragile handling

Here’s the deal: until you run your actual product, you don’t know where damage hides. Use a structured Factory Acceptance Test (FAT) and Site Acceptance Test (SAT) to prove performance.

Acceptance criteria (adjust to your product):

- Breakage/damage rate: ≤ 1% across representative batches.

- Alignment drift/misalignment: ≤ 0.5% of units requiring manual intervention.

- Throughput stability: within ±5% of target at nominal speed.

- Cleanability verification: meets sanitation plan (visual inspection + swab test where applicable).

Suggested protocol

- Build test sets that reflect extremes: lightest/heaviest, smallest/largest, slickest/roughest packaging.

- Test speeds: slow, nominal, and high; include stops/starts to exercise ZPA logic.

- Transfers: instrument the most critical handoffs; record gaps, tip rates, and scuff observations.

- ESD: in EPAs, verify resistance‑to‑ground and ionizer balance before live runs per program procedures.

- Documentation: keep calibration certificates, test logs, deviations, and operator training records.

Micro‑examples across industries

Bakery pastries (washdown, soft packages)

Disclosure: BisonConvey is our product. In a pastry packing line, a short modular plastic belt with tight‑transfer nose rollers feeds cartons onto an incline with side guards and UHMW rail liners. Zero‑pressure accumulation holds cartons before a checkweigher, eliminating back pressure and cracked icing. Drives use gentle ramps via the VFD to avoid jarring starts. Stainless frames and open‑grid belting support daily washdown in line with 3‑A/EHEDG principles. The combination reduces scuffing at the nosebar and stabilizes dwell without product‑to‑product contact.

Electronics PCBs (EPA with ESD control)

An EPA transfer between SMT and inspection uses a dissipative flat belt, bonded/grounded frames, and zone sensors for ZPA before the AOI cell. Ionizers address unavoidable insulators (tray materials). Footwear/flooring resistance and body‑voltage checks are verified per the facility’s S20.20 program. Gentle acceleration profiles prevent vibration spikes that can unseat components prior to reflow or handling.

Glass bottles (tight transfers, low back pressure)

A container line replaces dead plates with dead‑plate‑free tight transfers and employs roller‑top accumulation to decouple drive forces from product contact. Synchronized speeds at each handoff and knife‑edge transfers reduce tip‑over risk and neck scuffing. Operators report fewer stoppages from toppled bottles and smoother re‑starts after short holds.

Maintenance, troubleshooting, and spares: what to plan

Keep a short list and stick to it.

- Belts: Inspect tension, tracking, and surface wear; schedule replacement before coatings degrade.

- Idlers/rollers: Check runout, bearings, and surface condition (UHMW/stainless/ceramic).

- Pulleys and drives: Verify lagging condition, alignment, and VFD parameters; update jerk‑limited profiles after changes.

- Sensors: Clean and test photoeyes; confirm zone logic.

- Grounds/ESD: Verify resistance‑to‑ground and ionizer performance per your audit cadence.

- Sanitation: Audit cleanability and inspect potential harborage points after modifications.

Next steps

Want a structured spec for your fragile‑handling upgrade? Share product parameters and hygiene/ESD needs, and we’ll propose a short validation plan with zone logic and transfer options.

References and standards

For accumulation strategies and zone logic, see Interroll’s ZoneControl/MultiControl documentation and Hytrol’s zero‑pressure accumulation overview. For knife‑edge transfers and UHMW accessories, consult Dorner’s transfer method pros and cons and their manuals on AquPruf nosebar options y el 3200 Series. For dead‑plate‑free tight transfers in bottle lines, see Intralox’s overview on tight transfers without dead plates. For drive profiles that reduce jerk, see Rockwell’s TotalFORCE control features. For sanitary design in food‑contact equipment, review the FDA’s CGMP overview alongside the 3‑A SSI primer y el EHEDG Yearbook 2023.