PRODUCTS

Industrial Conveyor Belts & Components

Application-focused product families: choose by belt type, component type or working condition (heat, impact, corrosion, high incline). Each product card links to a dedicated technical detail page.

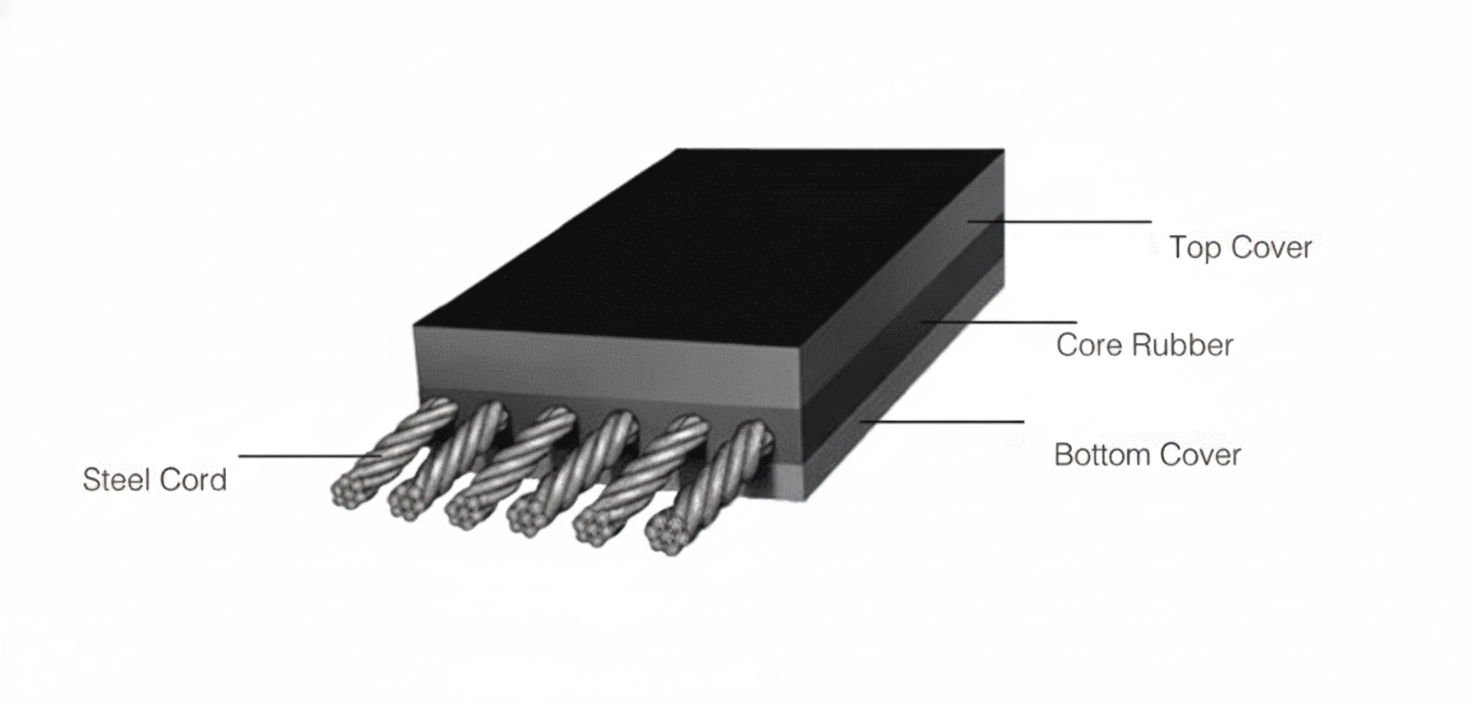

Steel Cord Conveyor Belts

High-strength, low-elongation belt designed for long-distance, heavy-duty material conveying.

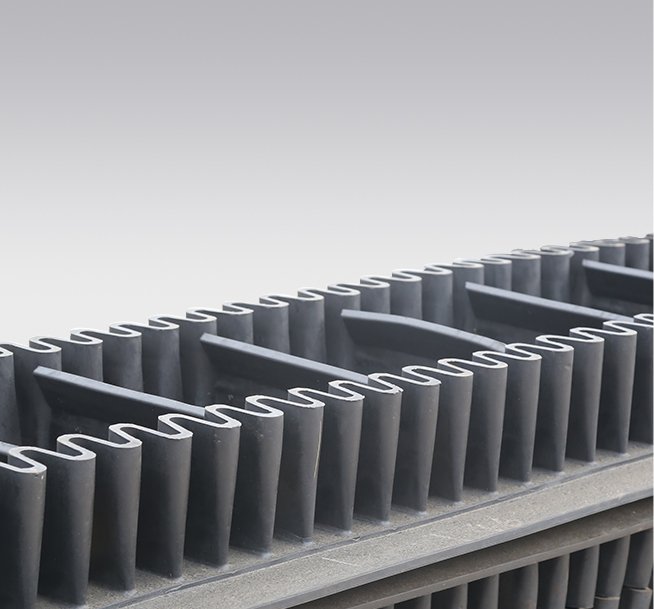

Sidewall Conveyor Belt

Large-angle conveying with strong lateral rigidity, ideal for bulk materials and compact system layouts.

.png)

Chevron Conveyor Belt

Anti-slip patterned belt for steep-angle, wet, or loose-material conveying applications.

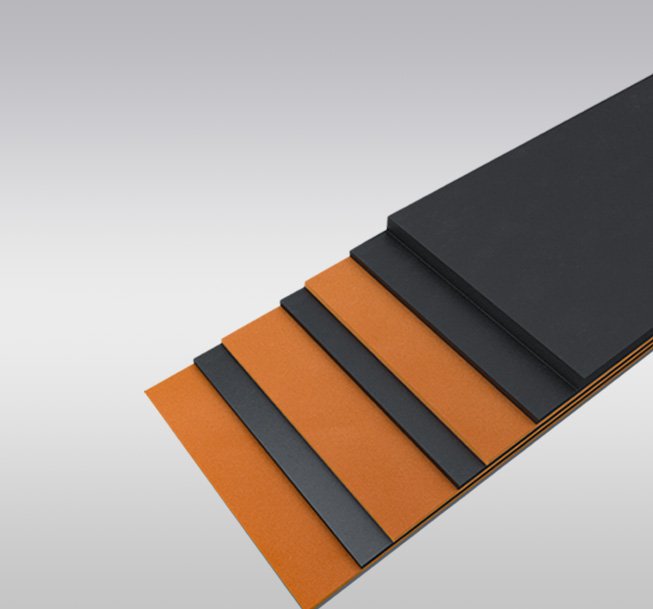

Fabric Conveyor Belt

Versatile multi-ply belt for general industrial use, available in NN, EP, and cotton canvas structures.

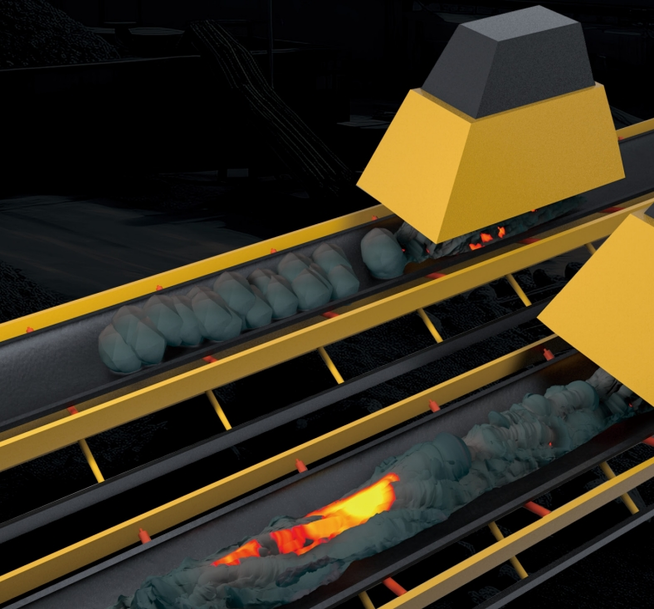

Heat Resistant Conveyor Belt

Engineered for 100–180°C continuous heat and up to 250°C short-term high-temperature conveying.

Pipe Conveyor Belt

Enclosed conveying system for dust-free, environmentally protected, curved-route transportation.

Impact Idler

Polyurethane/rubber shock-absorbing rollers designed to protect belts at heavy-impact loading points.

Stainless Steel Idler

Corrosion-proof, anti-magnetic roller with 5–8× the lifespan of conventional steel idlers.

Ceramic Lagged Idler

Ultra-wear-resistant, non-adhesive ceramic roller ideal for extreme temperature and abrasive conditions.

UHMWPE Idler

Lightweight, ultra-low-friction roller with exceptional wear resistance and energy-saving performance.

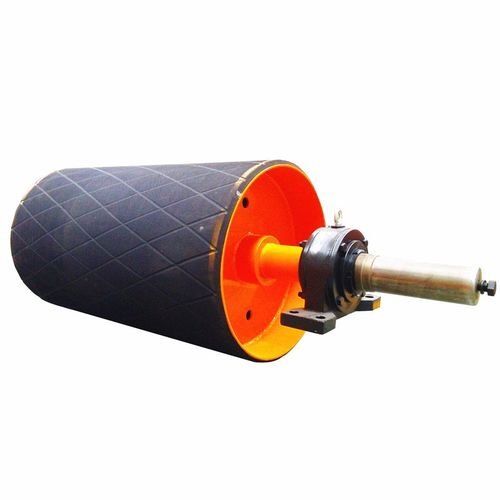

Drive Pulley

High-friction, heavy-load drive pulley providing stable 24/7 operation with long-life lagging.

Bend Pulley

Precision guiding pulley designed to reduce belt misalignment and optimize system stability.

Motorized Drive Roller (MDR)

Integrated motor-drum design for compact, energy-efficient conveying and sorting systems.

Rubber-Lagged Pulley

Vulcanized rubber-coated pulley that increases friction 30–50% and extends belt life significantly.

Self-Aligning Idler

Automatic belt-tracking idler system preventing belt deviation and reducing wear and material spillage.

Not Sure Which Product Fits Your Application?

Share your material type, capacity, conveying length and working conditions. Our engineering team will recommend a matching belt, idler and pulley configuration.