Conveyor Roller Vibration Troubleshooting: Causes, Diagnosis, and Fixes

Step-by-step field guide to diagnose and fix conveyor roller vibration—safety checks, measurements, repair vs. replace criteria, and prevention tips.

Technical articles, case studies and best practices on conveyor belts, idlers, pulleys and bulk material handling systems for mining, ports, steel, cement and power industries.

Step-by-step field guide to diagnose and fix conveyor roller vibration—safety checks, measurements, repair vs. replace criteria, and prevention tips.

Practical, standards‑aligned dust control strategies for conveyor systems—transfer‑point containment, suppression, filtration, and maintenance for operations and reliability teams.

Practical guide for engineers: choose conveyor slope angles for bulk materials, with material limits, cleat/sidewall solutions, transfer & maintenance tips.

Step-by-step, standards‑aligned how-to guide to cut conveyor kWh/ton — audits, LRR belts, idlers, VFDs, cleaners, and verification.

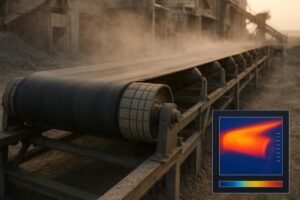

Step-by-step guide to diagnose and reduce conveyor belt temperature rise—measure hotspots, prioritize causes, apply LRR covers, idler and lagging fixes, and verify results.

Complete, field-tested guide to conveyor belt calibration — step-by-step methods, speed-sensor verification, LOTO safety, troubleshooting, and calibration templates.

Share your requirements and our specialists will provide pricing and technical recommendations.

Talk with BisonConvey about conveyor belt selection, idler configuration or upgrading existing systems for higher reliability and lower maintenance.