PRODUCTS

Conveyor Pulleys and Idlers

Built for heavy-duty conveying—high-traction pulleys and long-life idlers engineered for dust, moisture, corrosion, and continuous operation.

Conveyor Pulleys

Our pulley lineup covers the key power and routing components used in belt conveyors, with configuration options designed to improve traction, reduce slippage, and maintain stable belt travel in demanding environments.

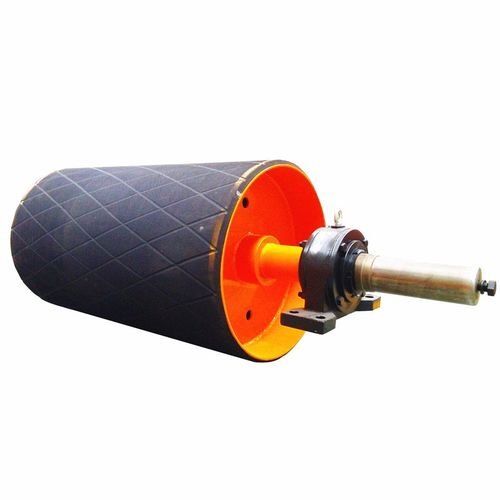

Drive Pulley (Transmission Drum)

Designed as the primary power-transfer component, with surface options that increase friction by 30%–50% (rubber lagging or ceramic surface) to eliminate belt slippage. Heavy-load durability is supported by a thickened drum wall (10–30 mm) and integrated shaft design for deformation and fatigue resistance. Hot-vulcanized rubber lagging delivers a wear-resistant layer with 5–10 years service life and supports 24/7 continuous operation.

Bend Pulley (Directional/Reversing Drum)

Used to optimize belt path alignment and increase stability, helping reduce belt misalignment. Available with customizable diameters (200–2000 mm) and surface treatments such as zinc-plated or stainless steel for humid and corrosive environments. Lightweight construction options (e.g., hollow shaft or lightweight alloys) can reduce overall load and energy consumption.

Rubber-Lagged Pulley

Engineered for high traction and high wear scenarios, the rubber-lagged surface increases friction by 30%–50% versus bare steel pulleys to ensure efficient power transmission and prevent slippage. Hot vulcanization combined with high-hardness rubber provides a 5–10 year wear layer lifespan and withstands impact from sharp materials such as ore and coke. It can extend conveyor belt life by 30%–50%, enable 10-year maintenance-free operation in heavy-duty scenarios, and reduce comprehensive O&M costs by 60%.

Motorized Drive Roller (MDR)

A highly integrated unit combining motor and drum to reduce external transmission components, save footprint, and simplify installation. It is widely used in conveyors, sorting systems, logistics warehousing, and mining/port scenarios—especially where space is limited or environments are complex, including humidity, mud, and high dust conditions

Conveyor Idlers

Our idler portfolio focuses on impact resistance, corrosion protection, wear reduction, and stable tracking—helping improve conveyor efficiency and reduce unscheduled downtime across mining, metallurgy, ports, and other heavy-duty applications.

Impact Idler

Built for high-impact transfer zones using a polymer polyurethane/rubber composite ring array with an elastic buffer layer. The reinforced roller body and buffer design balance impact resistance and load-bearing strength, supporting heavy-duty conveying where large ore or metal shavings create strong impacts—helping extend the service life of belts and drum components.

Stainless Steel Idler

Manufactured from high-quality stainless steel formed by a spinning process for high strength and deformation resistance. Demonstrated 5–8× longer service life versus conventional rollers and resists corrosion from acids, alkalis, salts, and aggressive chemical media. Commonly used in underground mines, thermal power plants, and ports; also designed to operate reliably under iron removers by resisting strong magnetic field adsorption.

Ceramic Lagged Idler

Designed for extreme high temperature, strong corrosion, and high wear conditions. Fully sealed ends with plastic labyrinth seals prevent oil/grease leakage and enable long-term sealed operation. The ceramic surface forms an oxide film that does not adhere/react, helping material fall off naturally; service life is 2–3× longer than steel rollers and can reduce belt wear while helping prevent belt deviation—lowering total conveyor cost and maintenance hours.

UHMWPE Idler

Built around ultra-high molecular weight polyethylene for ultra-high wear resistance, ultra-low friction, and strong anti-adhesion. It runs with low noise and low rotational resistance, offers strong mechanical strength against repeated impacts/vibrations, and is lightweight for easier replacement and energy efficiency. Wide temperature adaptability supports long-term operation from -49°C to 90°C, and it is widely used in high-dust and highly corrosive conditions with strong cost-effectiveness.

Self-Aligning Idler (Self-Aligning Bracket)

A simple-structure solution with a significant self-aligning effect to prevent belt deviation, material leakage, and abnormal equipment wear. Reinforced materials and techniques support long-term stable operation under high-load conditions.

- Traction & Anti-slip Options:Rubber lagging / ceramic surface to improve friction and reduce slippage.

- Built for Harsh Duty:High impact handling, wear/corrosion resistance, humid/muddy/dusty environments coverage.

- Customization for Your Conveyor:Diameter/surface/material selections (e.g., bend pulley customizable Ø200–2000mm; zinc-plated/stainless options).

Impact Idler

Polyurethane/rubber shock-absorbing rollers designed to protect belts at heavy-impact loading points.

Stainless Steel Idler

Corrosion-proof, anti-magnetic roller with 5–8× the lifespan of conventional steel idlers.

Ceramic Lagged Idler

Ultra-wear-resistant, non-adhesive ceramic roller ideal for extreme temperature and abrasive conditions.

UHMWPE Idler

Lightweight, ultra-low-friction roller with exceptional wear resistance and energy-saving performance.

Drive Pulley

High-friction, heavy-load drive pulley providing stable 24/7 operation with long-life lagging.

Bend Pulley

Precision guiding pulley designed to reduce belt misalignment and optimize system stability.

Motorized Drive Roller (MDR)

Integrated motor-drum design for compact, energy-efficient conveying and sorting systems.

Rubber-Lagged Pulley

Vulcanized rubber-coated pulley that increases friction 30–50% and extends belt life significantly.

Self-Aligning Idler

Automatic belt-tracking idler system preventing belt deviation and reducing wear and material spillage.

OEM/ODM & Customization

We support application-driven configurations to match site conditions and conveyor layouts, including surface treatments and material selections for humid, dusty, corrosive, and high-wear environments.

Customization highlights

-

Bend pulley diameter customization 200–2000 mm, with zinc-plated or stainless options for corrosion resistance.

-

Traction solutions: rubber lagging / ceramic surfaces to increase friction and reduce slippage.

-

Material-driven idler selection: stainless for chemical corrosion resistance; ceramic for high-wear/high-temp; UHMWPE for low friction and anti-adhesion.

Not Sure Which Product Fits Your Application?

Share your material type, capacity, conveying length and working conditions. Our engineering team will recommend a matching belt, idler and pulley configuration.

FAQs

Q1. What pulley option best prevents belt slippage?

Drive pulleys with rubber lagging or ceramic surfaces increase friction by 30%–50%, effectively eliminating slippage.

Q2. When should I choose a rubber-lagged pulley?

For heavy-duty, humid, and high-wear scenarios where you need higher traction and longer wear life; documented benefits include belt life extension (30%–50%) and major O&M reduction (60%) in heavy-duty cases.

Q3. What idler is recommended for high-impact loading zones?

Impact idlers using polyurethane/rubber composite buffer rings are built to handle strong impacts from large ores and metal shavings.

Q4. Which idler is best for corrosive or chemical environments?

Stainless steel idlers resist acids, alkalis, salts, and aggressive chemical media; ceramic lagged idlers also deliver strong corrosion resistance and high wear performance.

Q5. Can ceramic idlers help reduce belt deviation?

Yes—ceramic lagged idlers are designed to prevent belt deviation and reduce belt wear, with 2–3× life over steel rollers.

Q6. What makes UHMWPE idlers suitable for harsh sites?

They combine ultra-low friction, anti-adhesion, low noise, and a wide operating range (-49°C to 90°C), and are widely used in high-dust and corrosive conditions.

Q7. How do self-aligning idlers improve conveyor stability?

They provide a significant self-aligning effect to prevent belt deviation, material leakage, and abnormal wear under high load.